Intelligent agents in AI are redefining how manufacturing companies operate. From predictive maintenance to real-time supply chain optimization, these autonomous systems are driving smarter decisions across the production floor. As industries embrace Industry 4.0, understanding the role of intelligent agents in AI is critical to staying competitive, minimizing downtime, and optimizing resources.

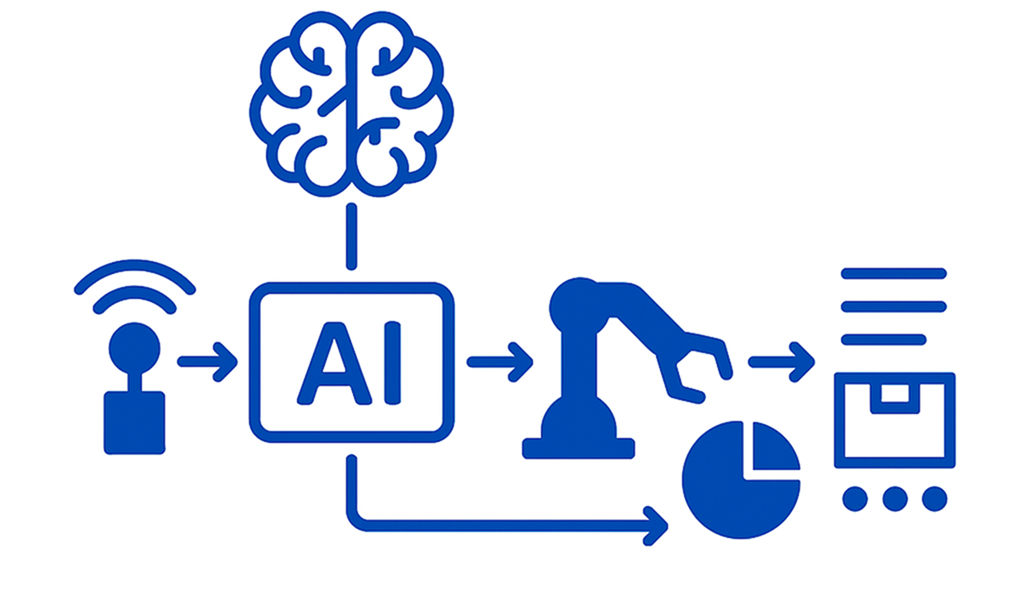

What is an intelligent agent in AI?

An intelligent agent in AI is a system capable of perceiving its environment, processing data, and taking autonomous actions to achieve specific goals. These agents range from simple reactive machines to complex learning systems capable of adapting over time.

There are several types of intelligent agents commonly used in AI:

- Simple reflex agents respond directly to stimuli with pre-programmed actions.

- Model-based agents maintain an internal model of the world to inform their decisions.

- Goal-based agents act with the purpose of achieving defined objectives.

- Finally, learning agents improve over time by analyzing outcomes and adjusting behavior accordingly.

These types form the basis of many AI-driven applications in manufacturing.

How manufacturing uses intelligent agents in AI

Manufacturing companies are leveraging intelligent agents in AI to streamline operations and enhance decision-making. These agents provide real-time insights and automate tasks that previously required manual intervention.

According to Worxwide, intelligent agents monitor sensor data continuously, detecting anomalies and forecasting equipment issues before breakdowns occur. For process optimization, CodeNinja reports that agents analyze historical and real-time data to adjust workflows and resource allocation dynamically. When disruptions hit the supply chain, agents evaluate inventory levels, propose alternative suppliers, and realign production schedules to prevent delays, as outlined by SmythOS. In quality control, Flowable shows that AI agents equipped with vision capabilities identify subtle defects with high precision, improving product reliability.

Some key applications include:

- Real-time anomaly detection for proactive maintenance scheduling

- Data-driven workflow adjustments to minimize bottlenecks

- Inventory rebalancing in response to supplier disruptions

- Enhanced inspection accuracy with computer vision

Benefits for manufacturing companies

Intelligent agents in AI offer significant advantages for manufacturers by making operations more agile, cost-efficient, and reliable. Their ability to act quickly and learn from data positions them as key enablers of smart manufacturing.

Master of Code emphasizes that reduced downtime is one of the most valuable benefits, with predictive systems ensuring machines are serviced before issues arise. Operational efficiency also improves through optimized logistics, precise inventory management, and smoother production planning, as highlighted by Automation Anywhere.

Key benefits include:

Lower operational costs through predictive maintenance

Increased productivity via optimized task scheduling

Higher product quality from AI-driven inspections

More resilient supply chains and logistics operations

Challenges of using intelligent agents in AI

While the benefits of intelligent agents in AI are compelling, successful implementation requires addressing several key challenges. Companies must evaluate their infrastructure and organizational readiness to fully harness the technology.

A strong data foundation is critical, as agents rely on timely and accurate information to function effectively. Integrating these systems into legacy environments can be complex, and may require investment in connectivity and analytics platforms. Additionally, workforce adaptation is essential, teams need training to collaborate with AI tools and interpret their outputs. The overall system complexity can increase as companies adopt multiple specialized agents, necessitating robust monitoring and maintenance protocols.

Intelligent agents in AI are no longer just a futuristic concept, they are practical tools reshaping manufacturing. From Siemens to SAP, leaders in the industry are already seeing gains in uptime, cost reduction, and agility. As the technology matures, its potential to drive productivity and resilience will only grow. For manufacturers aiming to thrive in the era of Industry 4.0, intelligent agents are fast becoming indispensable.

Need automation tools in manufacturing?

Related Articles

AI Agents Explained in Simple Terms

Discover what AI agents are, how they work, and why intelligent agents are reshaping automation across industries.

AI Solutions for HR That Transform Hiring and Retention

AI solutions for HR are transforming hiring and retention with faster recruitment, better cultural fit, and lower turnover rates.

Cross-Chain dApps Are Shaping Web3

Cross-chain dApps are shaping Web3 by streamlining UX, improving contract monitoring, and bridging fragmented blockchain ecosystems.